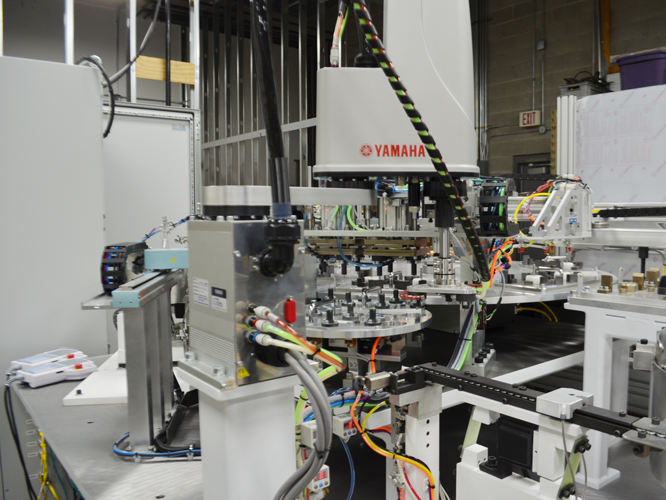

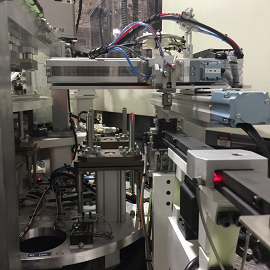

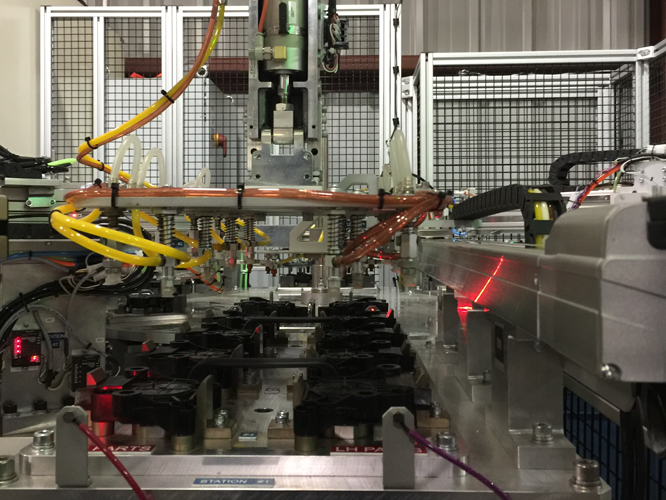

Base Plate Assembly Automation 1025 Honda

Project Overview

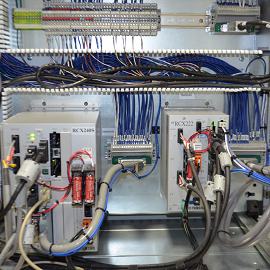

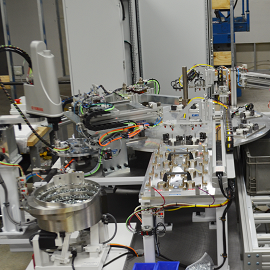

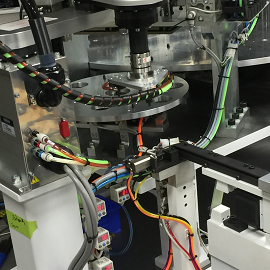

This turnkey system fully assembles an automotive window bracket. The machine receives eight brackets from a Star robot. A Yamaha servo picks two brackets at a time and loads them onto the main dial. Station two presses three M5 flange nuts into the bracket assemblies. Station three presses four M6 flange nuts into the bracket assemblies. Station four inspects the bracket assemblies to ensure the nuts are present and pressed to the right depth. Station five then picks the bracket assemblies and places them into a tote. The tote system then removes a full tote and brings in an empty tote to allow the system to continuously run without interruption.